Rattan poles are harvested from various environments, cleaned to remove imperfections, and then split into core and...

-

Collections

add remove Modern Colours add removeFurniture add remove

-

Brown

add remove

Storage & Laundry

add removeTable Top

add remove -

Natural

add remove

-

White

add remove

-

Grey

add remove

-

Honey

add remove

- Stories

-

Collections

add remove Modern Colours add removeFurniture add remove

-

Brown

add remove

Storage & Laundry

add removeTable Top

add remove -

Natural

add remove

-

White

add remove

-

Grey

add remove

-

Honey

add remove

- Stories

- Home

-

Custom Menu

add remove

-

Women is Clothes & Fashion

Shop women is clothing and accessories and get inspired by the latest fashion trends.

Simple Style

A new flattering style with all the comfort of our linen.

Easy Layers

Endless styling possibilities in a collection full of versatile pieces.

-

Latest posts

-

Rattan's Journey: From Wild Growth to Woven ArtRead more

Rattan's Journey: From Wild Growth to Woven ArtRead more -

The Sustainable Harvest: Unveiling the Journey of Rattan from Forest to Craft04/07/2024Read more

The Sustainable Harvest: Unveiling the Journey of Rattan from Forest to Craft04/07/2024Read moreExploring the sustainable harvesting of rattan in Southeast Asia, detailing its journey from forest growth, through...

-

Crafted With Love: The Soul of Handmade Rattan - We asked the Weavers04/06/2024Read more

Crafted With Love: The Soul of Handmade Rattan - We asked the Weavers04/06/2024Read moreA short interview with one of our weavers to showcase their journey into this skilled craft making of our beautiful...

-

The Art of Rattan: From Harvest to Handcraft04/06/2024Read more

The Art of Rattan: From Harvest to Handcraft04/06/2024Read moreThe transformation of rattan from the forests of Southeast Asia into versatile, high-quality materials involves...

-

Master Artisans Weaving Wonders: The Craft Behind Our Exquisite Baskets04/06/2024Read more

Master Artisans Weaving Wonders: The Craft Behind Our Exquisite Baskets04/06/2024Read moreIn Myanmar, master craftsmen and women excel in the traditional art of rattan weaving, creating exquisite pieces with...

Blog categories

Search in blog

Archived posts

Rattan's Journey: From Wild Growth to Woven Art

Rattan, a naturally grown material, varies in size due to factors such as environment and age. It can be found in different regions, including waterlogged areas and mountainous, arid zones. Mountain-grown rattan often appears whiter and may be brittle due to the dry conditions, sometimes displaying a red hue in its natural grain, making it suitable for darker colors. Conversely, rattan from jungle floors is more flexible and less brittle, exhibiting softer grain tones ideal for maintaining natural color subtleties in home decor.

The harvesting process involves initial cleaning to remove natural imperfections like knots and bumps, a process known locally in Myanmar as "Chit." This is done using a sharp knife along each cane. After cleaning, the rattan is prepared for further processing.

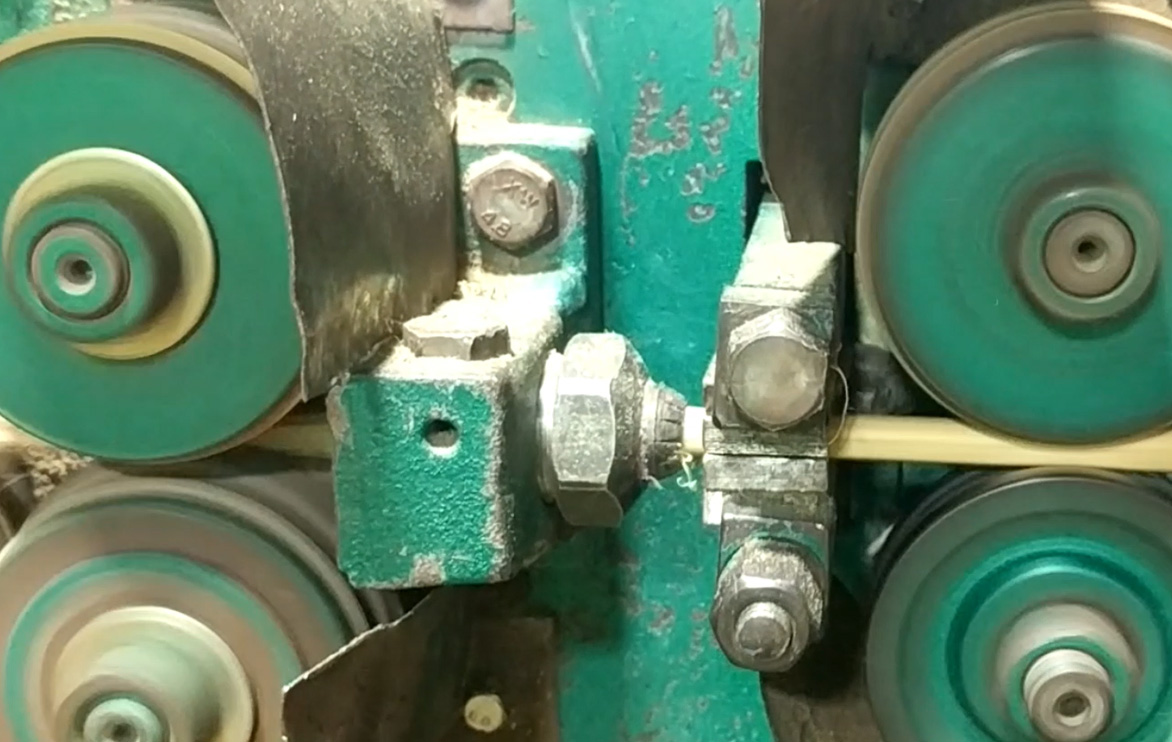

The manufacturing process involves splitting the rattan into the outer skin and the inner core. The inner core forms the sturdy frame of products, while the outer skin is woven around this frame. This skin is precisely cut by a machine into strips ranging from 2 to 5mm thick, depending on the product. Meanwhile, the inner poles are split into widths of 2.5 to 8mm. For instance, a small table-top pencil holder might use a 5mm pole with a 2.25mm woven skin, whereas a larger item like a laundry basket might use an 8mm core pole with a 2.75mm skin.

To ensure ease of weaving, the rough side of the split rattan skin is smoothed out by a second machine and bundled ready to be used by our weavers. This process guarantees that each strand of rattan skin is evenly smooth and ready for crafting into finished products. This meticulous preparation ensures consistency and quality across different items and orders.

Related posts

-

Master Artisans Weaving Wonders: The Craft Behind Our Exquisite Baskets

Posted in: Default category04/06/2024In Myanmar, master craftsmen and women excel in the traditional art of rattan weaving, creating exquisite pieces with...Read more

Master Artisans Weaving Wonders: The Craft Behind Our Exquisite Baskets

Posted in: Default category04/06/2024In Myanmar, master craftsmen and women excel in the traditional art of rattan weaving, creating exquisite pieces with...Read more -

The Art of Rattan: From Harvest to Handcraft

Posted in: Default category04/06/2024The transformation of rattan from the forests of Southeast Asia into versatile, high-quality materials involves...Read more

The Art of Rattan: From Harvest to Handcraft

Posted in: Default category04/06/2024The transformation of rattan from the forests of Southeast Asia into versatile, high-quality materials involves...Read more -

Crafted With Love: The Soul of Handmade Rattan - We asked the Weavers

Posted in: Default category04/06/2024A short interview with one of our weavers to showcase their journey into this skilled craft making of our beautiful...Read more

Crafted With Love: The Soul of Handmade Rattan - We asked the Weavers

Posted in: Default category04/06/2024A short interview with one of our weavers to showcase their journey into this skilled craft making of our beautiful...Read more -

The Sustainable Harvest: Unveiling the Journey of Rattan from Forest to Craft

Posted in: Default category04/07/2024Exploring the sustainable harvesting of rattan in Southeast Asia, detailing its journey from forest growth, through...Read more

The Sustainable Harvest: Unveiling the Journey of Rattan from Forest to Craft

Posted in: Default category04/07/2024Exploring the sustainable harvesting of rattan in Southeast Asia, detailing its journey from forest growth, through...Read more

Leave a comment